Formlabs Speciality Resins 1Kg

₹29,000.00

₹35,000.00

17% OFF

Key Description

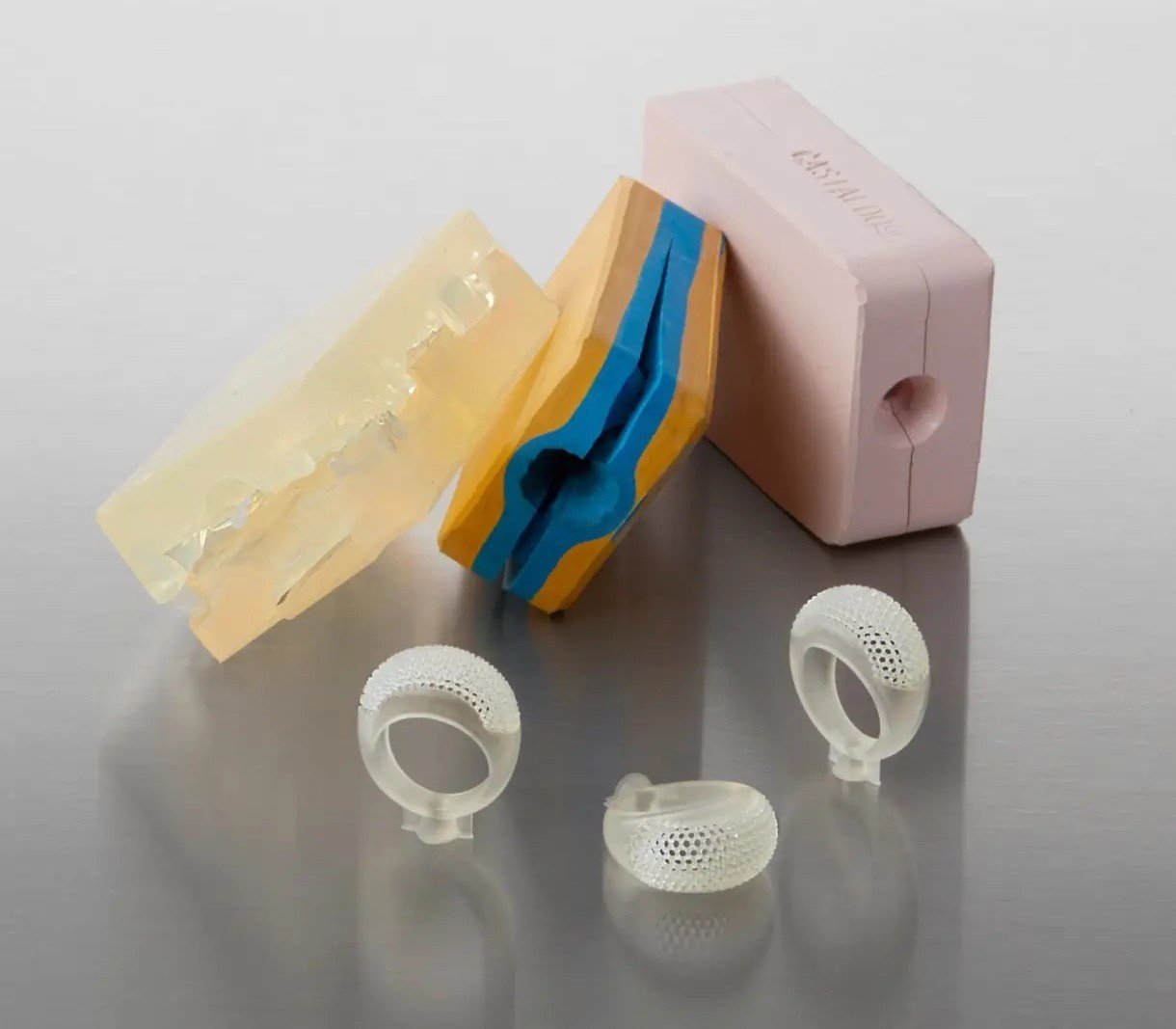

Rigid 10K Resin

- It is highly glass-filled and extremely stiff material that is similar to glass and fiber-filled thermoplastics.

- Use Rigid 10K Resin to rapidly produce molds, jigs, dies, and other tools, as well as functional prototypes and end use parts requiring dimensional accuracy and stability under high temperatures and pressures.

Tough 2000 Resin V2

- It is a rugged material with strength and stiffness comparable to ABS,

- combining toughness with high temperature and creep resistance.

- Tough 2000 Resin V2 excels in heavy-duty applications and delivers highly functional prototypes

- and end-use parts that resist shattering, deformation, and long-term wear.

- 79% elongation at break

- heat deflection temperature (HDT) of 70 °C,

- parts maintain structural integrity under mechanical and environmental stress.

The new formulation is darker with a matte finish, for presentation-ready parts with enhanced details and a smooth finish.

Tough 2000 Resin V2 is a new material formulation that leverages the technology of Form 4 Series printers to deliver 3x higher fracture toughness, improved temperature resistance, material longevity, and aesthetics compared to the previous version.

Silicone 40A Resin

- It is the first accessible 100% silicone 3D printing material, using Formlabs’ patent-pending Pure Silicone Technology™. Eliminate molding and labor-intensive casting processes by directly printing soft, pliable, and durable silicone parts in house in a matter of hours.

Fast Delivery

Within 3-5 business days7 Days Return

Easy refund policyCustomer Reviews

No reviews yet. Be the first to review!