ABS 1.75 mm Diameter 1Kg

₹799.00

₹899.00

11% OFF

Key Description

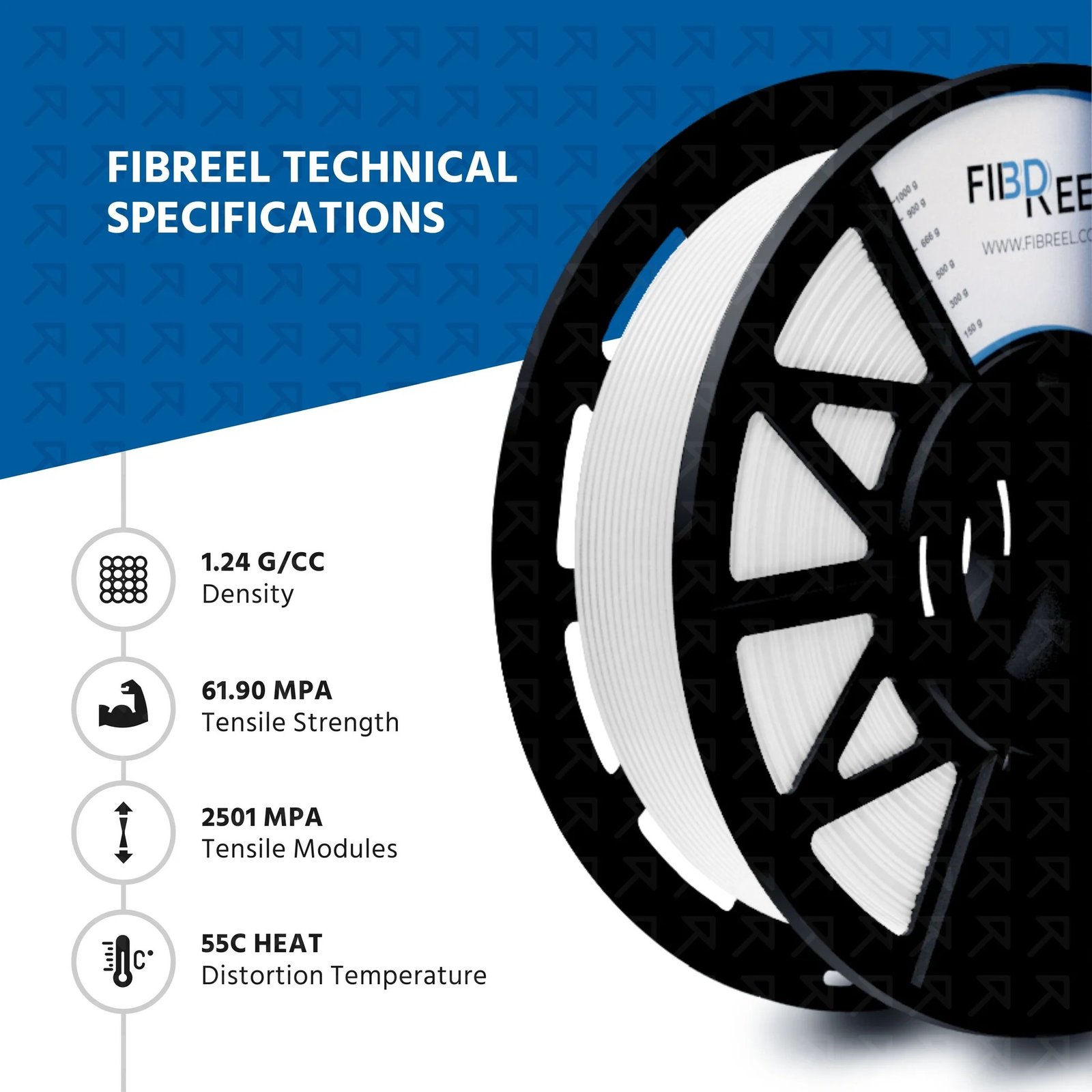

ABS White 1.75 mm (Acrylonitrile Butadiene Styrene) is low-cost and great for printing durable parts that need to withstand high temperatures. ABS is also popular due its good mechanical properties. It is known for its toughness and impact resistance, allowing one to print durable parts that can withstand extra wear and tear. ABS also has a higher glass transition temperature; hence the material can tolerate much higher temperatures before it begins to deform.

Printing Advice

1. ABS has a higher melting temperature than PETG so we recommend setting your hot end temperature between 235 and 260°C.

2. ALWAYS OFF the fan with ABS as it tends to cool the filament in the hot end and and leads to poor layer adhesion.

3. When printing larger parts, consider adding an enclosure around your printer to maintain a higher temperature around your print

4. Set your bed temperature to 100 – 130°C .

5. The best surface for printing ABS plastic is a PEI build plate or using Kapton tape or ABS Slurry

Fast Delivery

Within 3-5 business days7 Days Return

Easy refund policyCustomer Reviews

No reviews yet. Be the first to review!